The process of selecting a studio to design and create new stained glass windows differs somewhat from the process followed in choosing a restoration studio. In either case, however, it is important to visit the studios that you are considering for your stained glass window project. All too often, stained glass artists and studios are selected based on price alone, rather than quality of design and artist/studio integrity.

Stained glass should be an integral architectural element that enhances the character of the space of which it is a part. The quality of artistry and appropriateness of design for the space are most evident when one visits a space. Proper stained glass design requires specialized knowledge that allows this marriage of art and architecture to occur. For this reason, Stained Glass Resources does not offer catalog or ready-made window designs. Each window is unique, designed specifically for the client and the space.

The process usually begins with an inquiry from an appointed committee member or owner’s representative who calls to gather information and arrange an initial meeting. This initial meeting usually takes place at the site where the new windows are to be installed, and the goal of the meeting is to discuss the owner’s desires for the stained glass project. The Artist will usually present examples of past work and survey the site, or review site plans.

One other advantage to having a glass artist involved with a building project during the design phase is to help generate funds for the building project. Yes, window projects can actually be used to raise funds. In some cases, new stained glass projects have created so much enthusiasm for a building project that donors were eager to sponsor window panels that were priced by the project owner to cover not only the cost of the window, but some of the building costs as well.

Stained glass commissions begin with measurements and ideas. From there, sketches are generated and the process of design development evolves with the input of owners and committees and the talents of experiences glass designers and artisans.

Window Fabrication

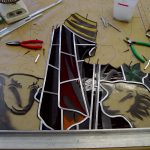

After design approval, the sketch becomes the model from which the full size drawings or “cartoons” are made. From the cartoon, glass cutting patterns and glazing drawings are made. The artist is involved in all phases of this work. It is during the cartooning stage that final glass selection takes place, and final design changes are made. Cartoons are not always pretty. They are marked to indicate glass selection, lead sizes and various finished dimensions. Once the cartoon is made, glass cutting patterns are cut out from the cut-line pattern.

Glass cutting begins after the patterns are cut. The glass utilized in the fabrication of stained glass windows comes from a variety of domestic and imported sources. Most often, we use the highest quality mouth-blown German antique glass in fabricating new work. Expert glass cutting allows for economical use of the vast range of colors and textures available within our glass inventory.

Once the glass is cut, any required surface treatment of the glass takes place. Some window designs call for painted or enameled glass, in which case vitreous paints are applied by the Artist, and fired in a kiln. These paints are kiln fired in order to permanently fuse the paint into the surface of the glass. Other surface treatments may include glass etching, cold painting, fusing, glue chipping, or beveling, to name a few.

Once the glass has been cut and painted, the leading of the panels begins. In the same manner that windows are releaded in the restoration process, new lead is used to craft the panels of newly designed windows. Meticulous care and attention is employed in the leading of all windows.

Following leading and soldering, the windows are cemented (weatherproofed). Windows undergoing the restoration process receive this treatment as well. At this stage, a putty-like material is used to fill any gaps between the glass and the lead channel used to hold the window together. This step also adds strength to the panel. Once cemented, the panel is cleaned and ready to be installed into its frame or sub-frame. If wire ties are needed to allow the panel to be secured to support bars, they are soldered onto panel at this time.

Scheduling, Installation and Site Work

The time required to execute a stained glass commission varies widely and is dependent upon a number of factors. How long will it take for the committee to approve a final window design? How many windows are included in the scope of work, and how large are they? What is the construction schedule like, and when will the frames be in place to receive the stained glass? These are but a few of the factors that may affect the length of time a commission takes. In general, a project can take anywhere from three months to three years, and may involve several phases that stretch out over a much longer period of time.

Once the window is designed and fabricated, work is almost complete. There is still the matter of installing the windows on site. Stained Glass Resources has a highly experienced and professional installation crew. As demonstrated by our Client Testimonial letters, we continue to provide excellent service whether we are at our own facility or yours. We work with you and keep you abreast of scheduling so that our presence does not disturb your normally scheduled activities. We manage our own scaffolding and lifts, and make sure that we leave behind a clean work site after proper installation of your frame and windows has been completed. We are dedicated to providing the highest quality services. Our goal is to meet or exceed your greatest expectation for your new project.